-

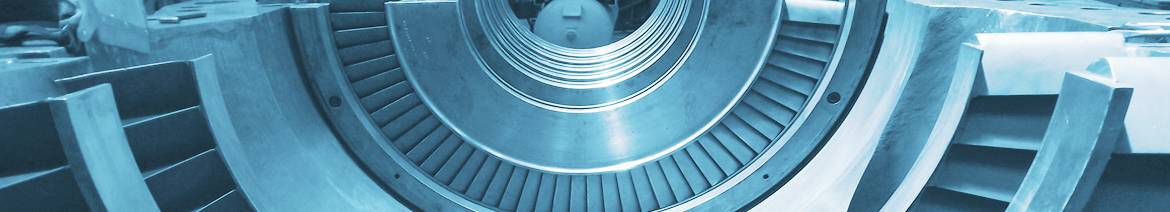

Title #1Turbine Rotor

Title #1Turbine Rotor -

Title #2Machining of rotor shaft

Title #2Machining of rotor shaft -

Title #3Turbine Rotor

Title #3Turbine Rotor -

Title #3Rotor

Title #3Rotor -

Title #48MW Turbine under assembly

Title #48MW Turbine under assembly -

Title #5CNC Centre lathe

Title #5CNC Centre lathe -

Title #6CNC Centre lathe

Title #6CNC Centre lathe -

Title #727MW Turbine after MRT

Title #727MW Turbine after MRT -

Title #8Arani Power factory

Title #8Arani Power factory -

Title #9MRT facility – Boiler house

Title #9MRT facility – Boiler house -

Title #10MRT facility – Boiler house

Title #10MRT facility – Boiler house -

Title #115.27MW Back Pressure Kalina Cycle Vapour turbine under MRT

Title #115.27MW Back Pressure Kalina Cycle Vapour turbine under MRT -

Title #16Back Pressure Turbine – After MRT

Title #16Back Pressure Turbine – After MRT -

Title #12Back Pressure Turbine under assembly

Title #12Back Pressure Turbine under assembly

Customer Centric Prod Dev

ARANI Team has adopted a customer-centric approach to deliver customized solutions. ARANI products are developed as per customer needs. ARANI does continual improvement to upgrade the existing designs, enabling quick response to ever changing customer requirements to deliver reliable and efficient Steam Turbines.

ARANI has developed turbine models up to 60 MW, which will operate upto 125 ata steam inlet pressure and 535°C steam inlet temperature. We also developed the Turbines to run with vapor (Steam and Ammonia mixture) which are used in Kalina Cycle.

The entire product development process encompasses designing of:

ARANI has developed turbine models up to 60 MW, which will operate upto 125 ata steam inlet pressure and 535°C steam inlet temperature. We also developed the Turbines to run with vapor (Steam and Ammonia mixture) which are used in Kalina Cycle.

The entire product development process encompasses designing of:

- Concept

- Valve Body and ESV

- HP and LP Casing

- Flow Path

- HP and LP Blades

- Rotor dynamics

- Control system

- Auxiliary system development and automation

- Automated Gland Sealing Systems

- Vapor Turbines

- Special Gland Sealing System

- Overview

- Customer Centric Prod Dev

- Tools & Softwares

- Testing & Validation

- Associations

-

-

-

- Arani Power Profile (2,077 kb)

- Arani Product Profile (1,446 kb)

- Refurbishment & Modernization (2,395 kb)

-

Chairman & Managing Director

Chairman & Managing Director

Shri Prabhulingeshwar Sugars & Chemicals Limited